Prior to the advent of BIM techniques and 3D CAD modeling, the structural design procedure was taken out using engineering analysis, and the design was described in a series of structural framework drawings. It is now probable to draw these 2D designs from previously hand-drawn 3D models. Usually, 2D drawings are used as design documents with the manufacturer providing complete structural information about the building or structure.

Sophisticated structural drawings software via https://www.bmoutsourcing.com/services/engineering try to gives designers the flexibility to create a number of custom elements, producing accurate geometric data with minimal errors. To create 3D models and images, the constructor first determines who the potential data users are, which processes are involved, and which data best supports the existing processes.

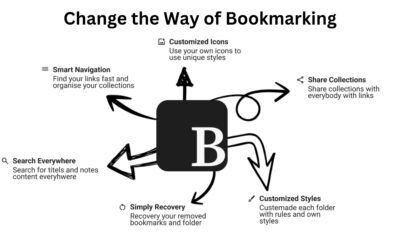

Image Source: Google

After determining what data will be of use to each end-user, how the data will be included in the design process, and what data format is needed, the user begins to enter the data into the model as needed. When installing structural steel, it is important to establish the desired construction schedule and sequence. In practice, the installer determines which areas of the structure will be created first and which areas to use in the future.

Several factors are included in determining the assembly sequence. Site configuration, crane capacity, crane access to the site, etc. Check the installation sequence. To do this, the manufacturer uses an independent database to track the material. Data from this database can also be directed to a 3D model to use graphic images. For the correct execution of construction and installation work, drawings for assembly and installation are sent to the manufacturer in a certain order.